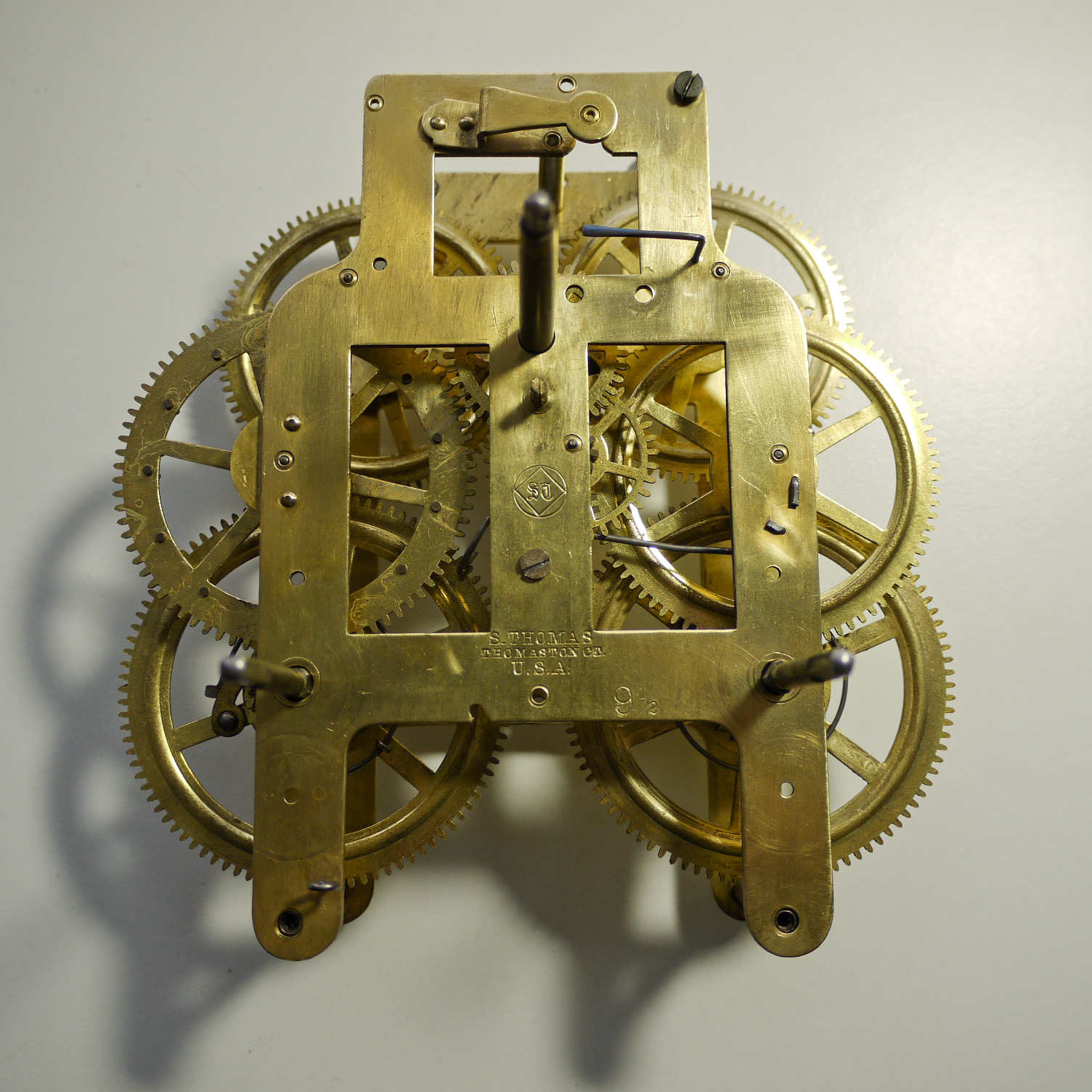

The entire movement has been stripped down and has been through the ultrasonic tank using the Horogreen 3-part process. Temporarily reassembled it now looks a lot better than it did:

The plates will be given a final polish before final assembly.

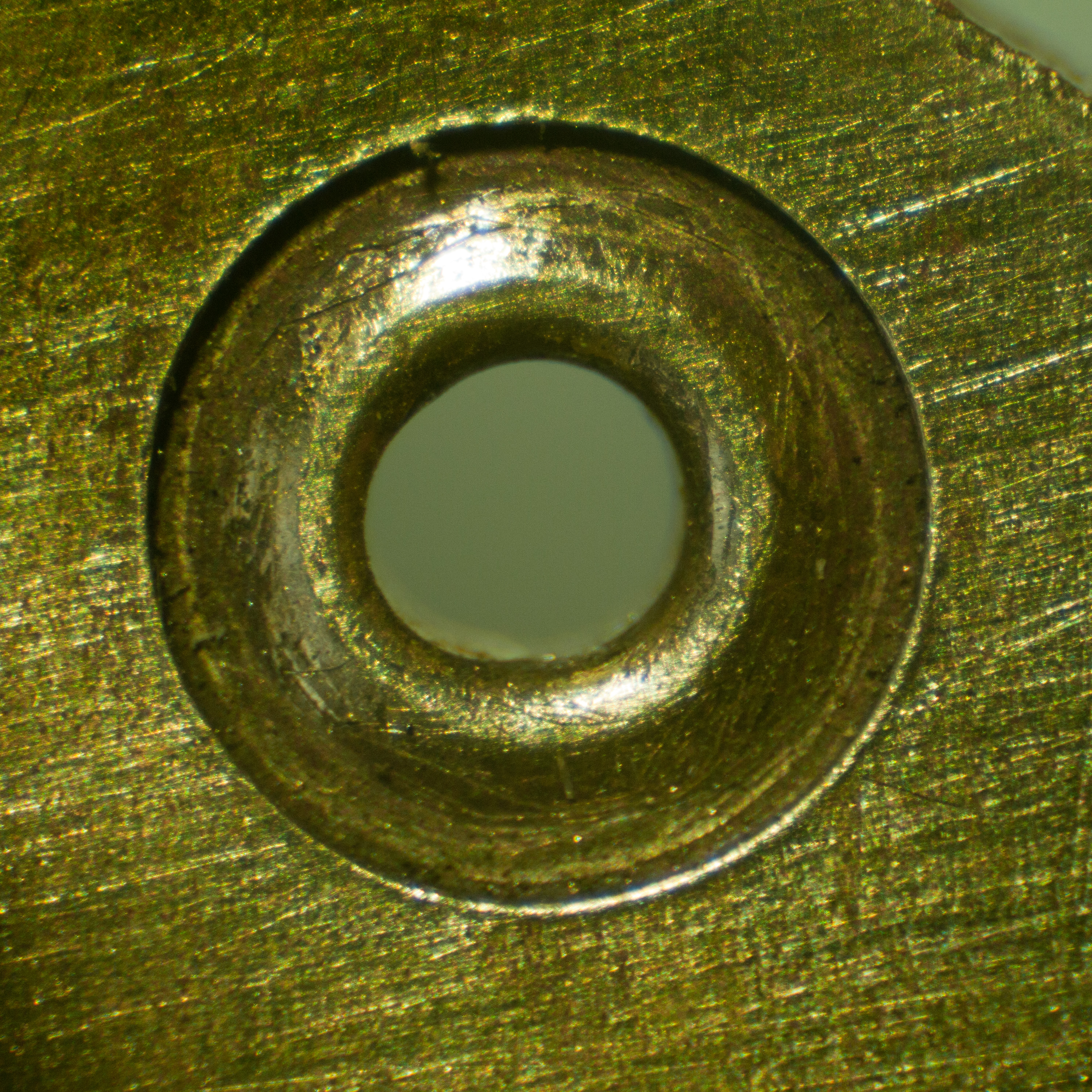

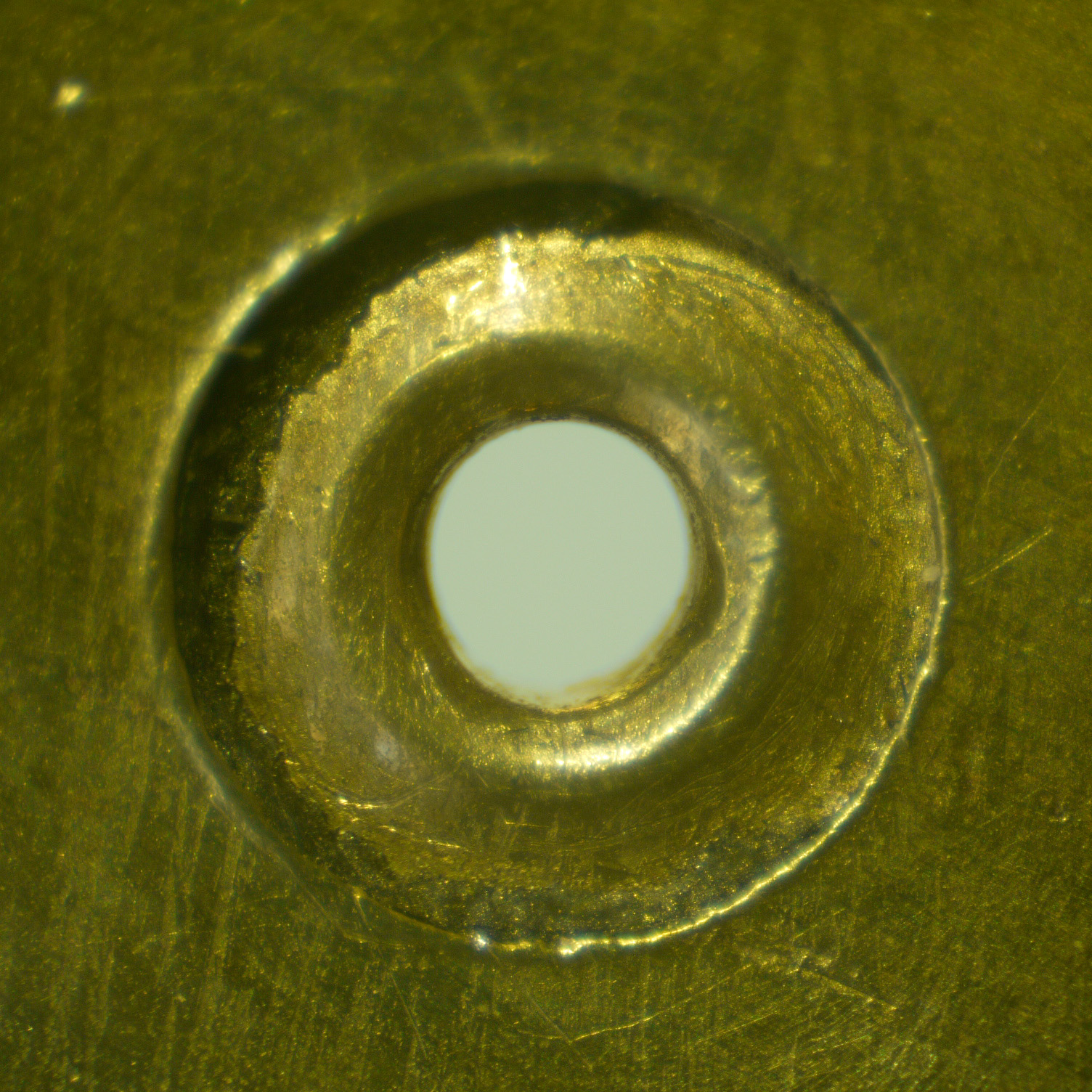

Now I could properly examine the pivot holes in the plates for wear; here’s two examples:

These are visibly oval, and the side-shake can be easily felt. Most of the pivot holes will need to be bushed – Bergeon bushes of the required sizes have been ordered from Cousins UK.

Most of the arbor pivots are worn as well:

Here’s one that has been turned in the lathe with a pivot file and burnisher, and awaits a final polish: