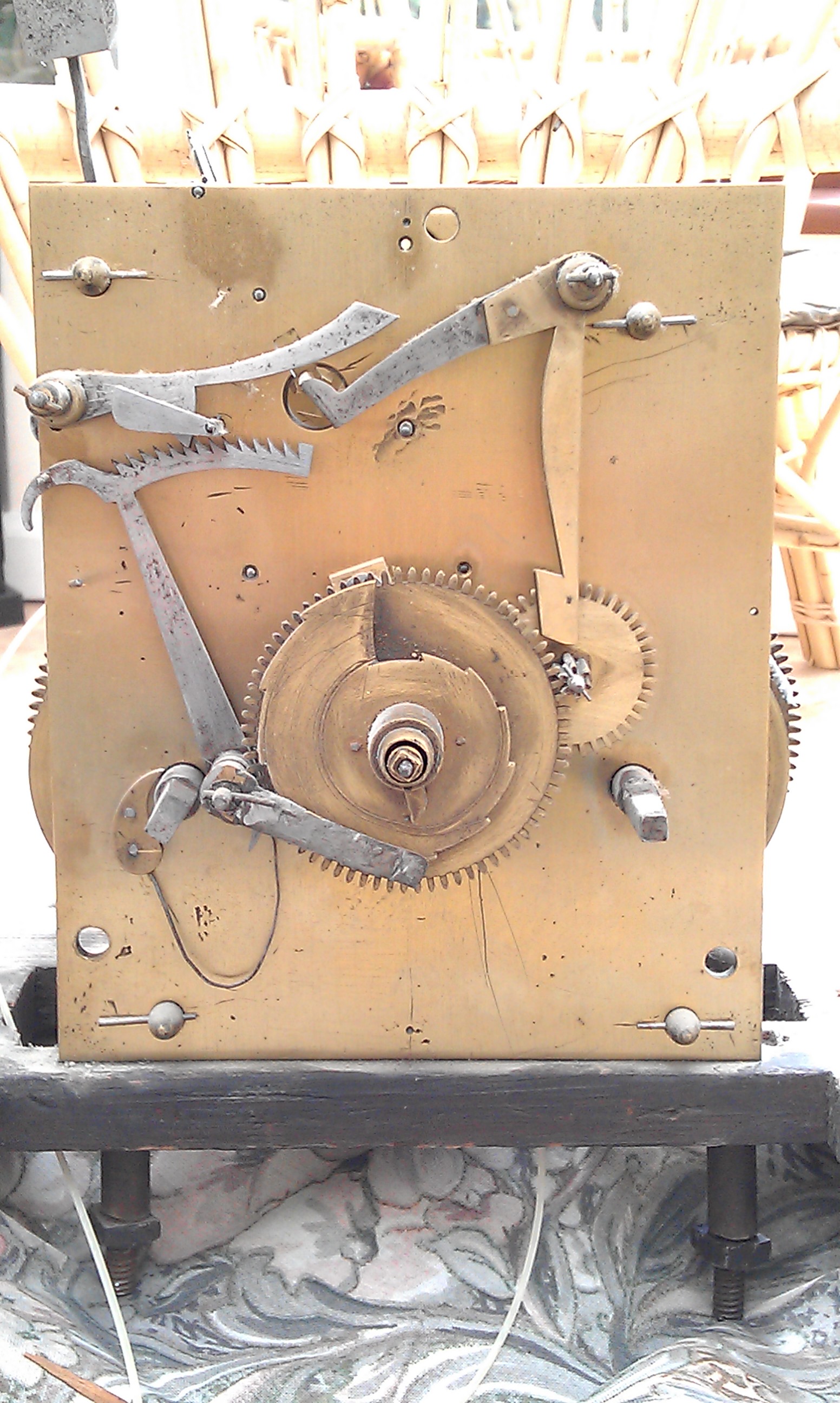

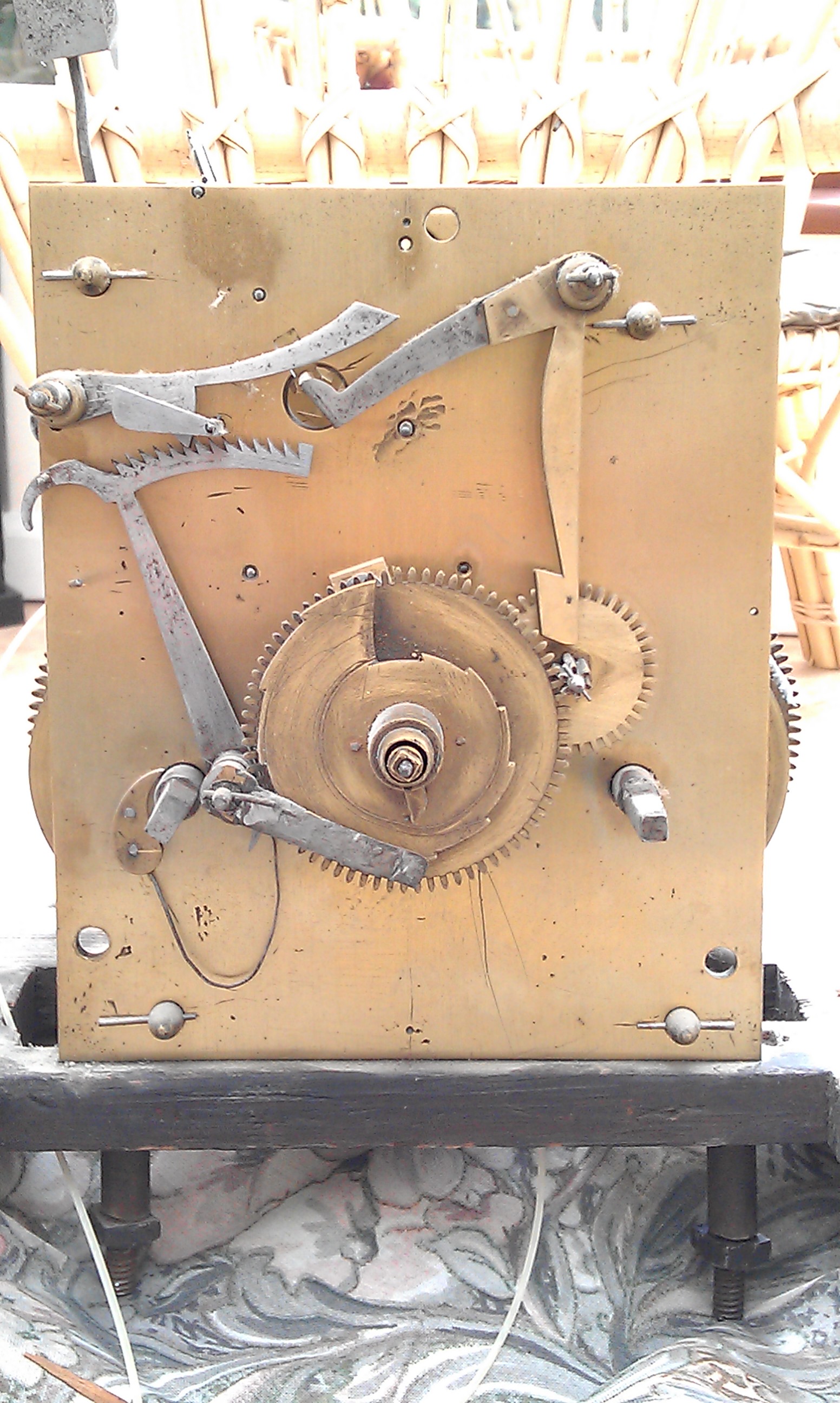

I was called to look at a long case clock that was having problems. The case was very shallow and I could see where the weights had been touching the inside of the front of the case, but moving the movement a fraction backwards caused the pendulum to rub on the backboard. The brass dial is inscribed with Jon Roberts Ruabon, who was active there until 1759 when he apparently moved to Wrexham. The owner kindly delivered the movement to me and I’ve been able to have a better look at the clock on the workshop stand. It’s revealed a bit of a puzzle. The clock runs for a while then simply stops, but the escapement (escape wheel/pallets combination) is not working correctly as it appears that either the escape wheel is on back-to-front or the pallets are incorrect – possibly due to a repair in the distant past. I’ve shot a brief video that shows the operation; it’s on youtube at:

http://www.youtube.com/watch?v=wkO0iO5QC1M

I’ve linked this video to an internet horology discussion group to try to sort out the best way to correct this whilst maintaining the integrity of the clock. There are also a couple of other things that have become apparent – the great wheel on the strike side is loose on the barrel arbor, the click spring on the going barrel needs to be replaced, and the rack hook spring is far too weak.

Dismantling the clock unfortunately revealed further wear and tear and more puzzles. The brass dial is attached to a false plate which suggests it is not original to the movement, but the false plate seems to be riveted onto the dial with very old rivets! There is also evidence of alterations to the false plate, namely pencil marks showing where additional cutouts were needed:

Many of the pivot holes in the plates had been hammered with a centre punch in an attempt to close them to compensate for pivot wear:

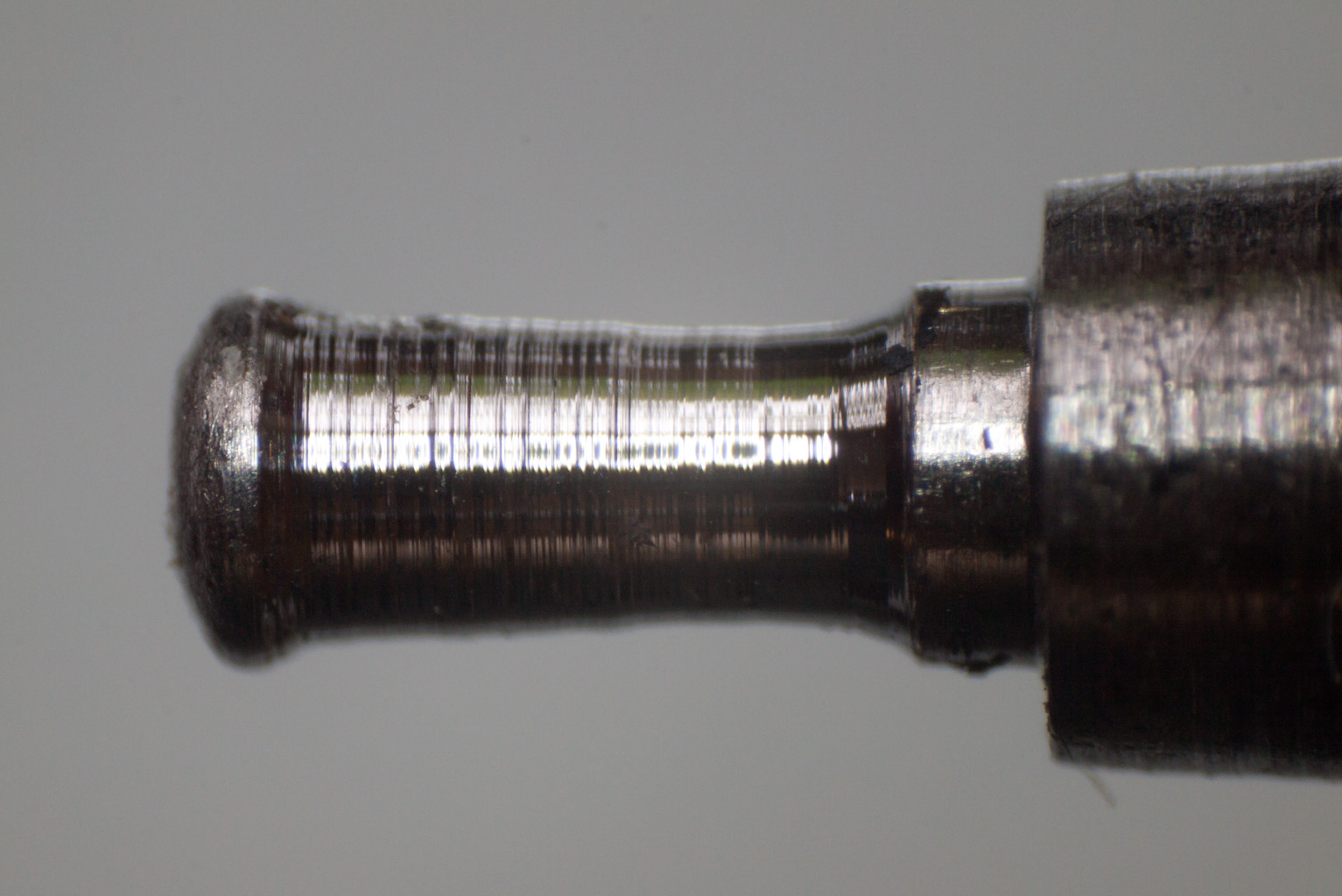

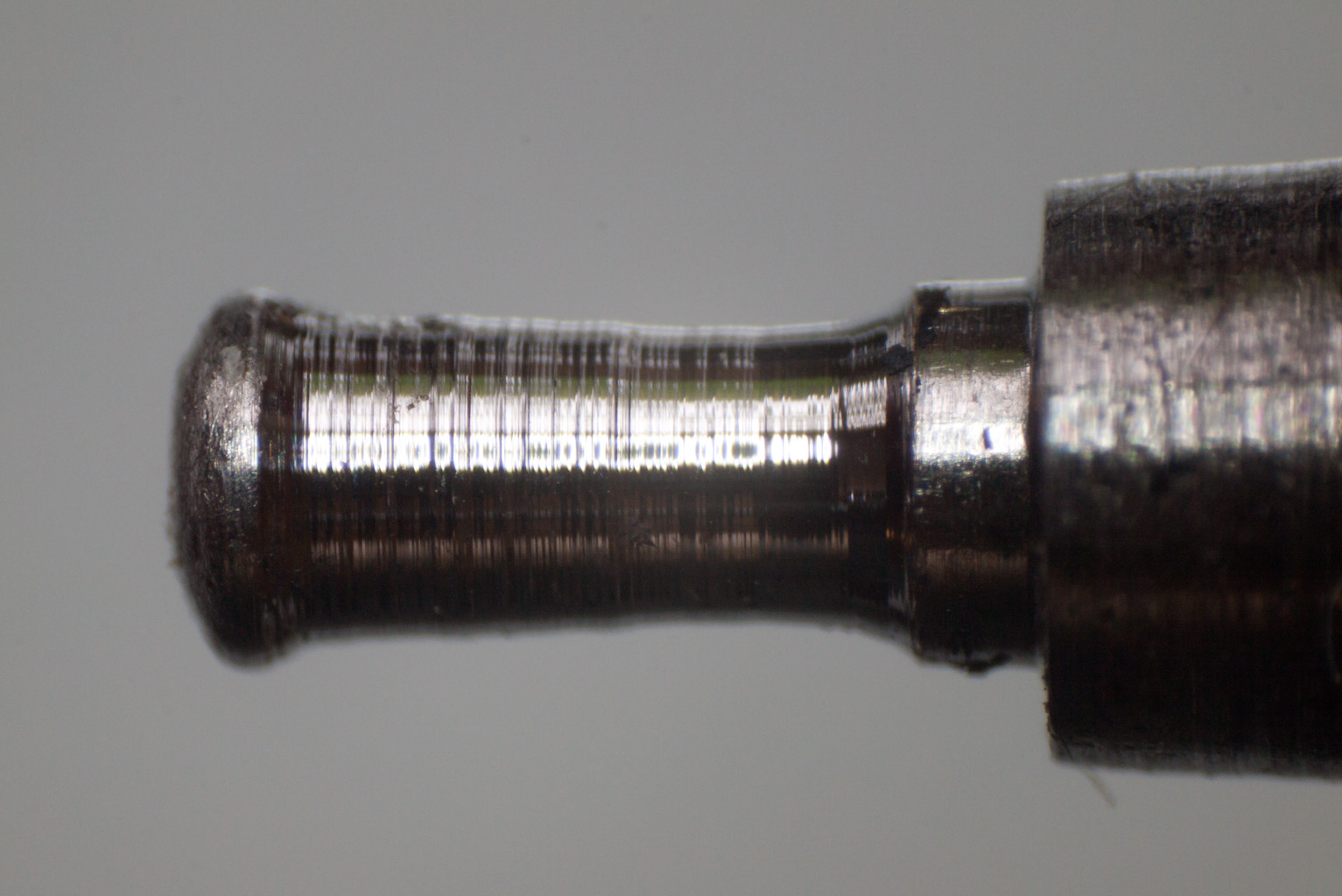

But in most cases this seems to have had the effect of creating a sharp edge to the pivot hole which has helped to wear the pivots badly:

Careful measurement leads me to believe that there is just enough metal remaining to turn down the pivots rather than have to re-pivot entirely. The affected pivot holes will of course have to be bushed.